Central AC compressor guide to getting you every detail about the system!

In this article, we will discuss in full detail:

- The AC compressor types.

- Functionality.

- Cost.

- Maintenance.

- Repair and replacement.

- Common problems.

- Warranty.

So, without a wait, let’s get into the details.

What is a Central AC compressor?

Your air conditioner comprises three major components that play a crucial role in changing the state of refrigerant to cool your home.

The three components are:

- Evaporator.

- Compressor.

- Condenser.

The compressor acts as the middleman in the cooling process, connecting the evaporator and the condenser.

The compressor’s job is to convert the gaseous, low-pressure refrigerant from the evaporator into a high-pressure, high-temperature gas before it enters the condenser unit.

It is fitted in the outdoor unit, also known as the condensing unit.

Understanding your central AC compressor helps you know how it functions and when it may need an AC repair service.

call 818-210-6669

Contact us 24/7 for your HVAC needs

How does the central AC compressor work?

The refrigerant leaves the evaporator inside your house as a low-pressure gas.

The temperature must be higher than the outside air to release the heat the refrigerant has absorbed.

It is where the compressor comes into play.

But that’s not it. To understand how an AC compressor actually functions, we need to learn in detail about the critical components of your central air conditioner.

Refrigerant

The refrigerant is a great substance and a form of gas in your AC system.

It evaporates in a matter of seconds and becomes a low-pressure gas.

As the refrigerant evaporates, it absorbs and collects heat

Also, it can be compressed from a high-pressure vapor into a low-pressure substance.

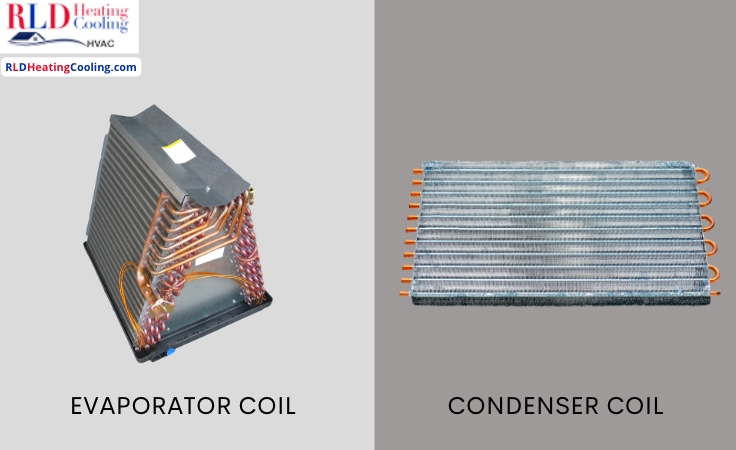

Evaporator coil

An evaporator coil is a radiator-like coil placed in the furnace or air handler inside your house.

As the refrigerant injects into the evaporator coil, it evaporates and transforms into a low-pressure gas.

As it evaporates, it collects and absorbs the heat inside your house, making it cooler.

The cold air is then pushed into the ductwork with the help of a motor blower.

Refrigerant line set

The refrigerant lines are copper wires that carry the refrigerant vapor from the evaporator coil inside your home to the condensing coil outside.

The other line carries cooled refrigerant vapor from the condenser unit to the evaporator unit.

The condensing unit

The condenser unit is where the compressor is located.

As the name suggests, the compressor compresses the high-pressure vapor into a low-pressure gas.

The refrigerant gets into the compressor through the suction lines.

Inside the compressor, a piston-like tool moves to and fro to draw the refrigerant in and then squeeze the gas together tightly.

When the refrigerant gas is squeezed, the molecules are packed and bound tightly, and both temperature and pressure of the refrigerant are raised.

The high-pressure refrigeration gas then leaves the compressor via the discharge line and flows towards the condenser.

The refrigerant then cools down and turns into a liquid form, which is returned to the evaporator, and the process continues.

Types of central AC compressors

The next thing we will discuss here is the five different types of AC compressors.

They are:

- Scroll compressors.

- Rotary compressors.

- Reciprocating compressors.

- Screw compressors.

- Centrifugal compressors.

They all are used in both commercial and residential air conditioning systems.

So, let’s get into the details of all of these.

Central AC compressor type #1: Scroll compressors

Scroll compressors are one of the most popular AC compressors.

They are mainly used to replace other types and styles of compressors when they fail.

Functionality

The scroll compressors at the core are made up of two identical spirals.

One spiral is fixated or stationary, and the other moves or vibrates, driven by a crank.

As denser, it travels through the system, leaving the compressor.

As the vibrating spiral rotates, it compresses the refrigerant, forming a high-pressure vapor.

The vapor then moves toward the center of the compressor, where it is further compressed and becomes denser.

Benefits

Scroll compressors offer many benefits, such as:

1) Efficiency: Scroll compressors are better than other compressors. They are not just efficient but also cost-friendly.

2) Super reliable: Many companies cover their scroll compressors with a 20-year or Lifetime warranty, which shows that the manufacturers have confidence in their products and the compressor is dependable.

3) Don’t fail quickly: Even if liquid, such as water, gets into the refrigerant, the compressor doesn’t fail. However, the problem with liquid is that it can’t be compressed. The floating spiral’s movement allows the moisture to push through the compressor without causing failure. But you should not make a mistake – moisture in the refrigerant is not a good thing. That’s why ACs include parts called filter driers to remove moisture from the refrigerant. Liquid substances falling into your refrigerant lines can damage the compressor if there is wiggle room.

4). No valves: Many compressor types have valves allowing the refrigerant to move in and out. It can cause easy wear and tear. Instead, the scrolls are better and more efficient.

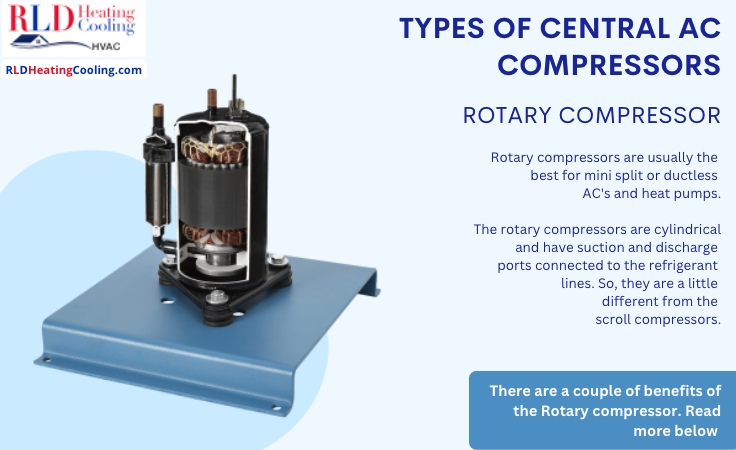

Central AC compressor type #2: Rotary compressors

Rotary compressors are typically the best choice for mini splits, ductless ACs, and heat pumps.

Let’s learn about its functionality.

Functionality

The rotary compressors are cylindrical and have suction and discharge ports connected to the refrigerant lines.

So, they are a little different from the scroll compressors.

The refrigerant enters the rotary compressors through the suction lines and exits via the discharge lines.

A roller is connected to the motor in the cylinder or compressor shell.

It rotates at the same speed as the motor.

The roll’s diameter is less than the diameter of the cylinder. A

s the roller rotates, the offset handwheel contacts the inner surface of the cylinder as it rotates.

In doing so, the refrigerant vapor is trapped on the side and compressed.

A spring-loaded fin is pressed against the side of the roller, preventing the compressed refrigerant vapor from escaping and ensuring it remains compressed.

The gas pressure will exceed the discharge line pressure, causing the vapor to be released back to the evaporator coil.

The suction valve opens, more refrigerant enters, and the cycle continues.

Benefits

There are a couple of benefits of the roller compressor:

1). Efficient: The units use 25% less energy than the other compressor types and are pretty efficient. The reason is that it maintains a perfect balance in temperature by adjusting the refrigerant’s circulation speed according to your house’s cooling requirements.

2). Quiet: The rotary compressors have a noise level of 40-55 decibels. On the contrary, the noise level of the scroll and other compressors ranges in the mid-60s to 70s.

Central AC compressor type #3: Reciprocating compressors

Reciprocating compressors are pretty old and obsolete in style.

They are usually used with the R22 refrigerant.

However, these refrigerants have become uncommon compared to the scroll and rotary compressors.

Functionality

Reciprocating means that the compressor’s mechanics – the pistons – move back and forth inside a cylinder. They are also known as a piston or positive displacement compressors.

During the low-pressure side, the refrigerant enters the suction tube.

The piston that moves to and fro compresses the gas to the point that it is discharged.

The valves on both sides open and close depending on the pressure inside the compressor.

The upward movement of the piston closes the suction valve, and the vapor is trapped inside the compressor.

As it is trapped and compressed, the pressure builds up and becomes more significant than the pressure on the discharge lines.

It forces the discharge lines to open, freeing up the vapor.

Benefits

The primary benefit of this compressor is that its design is straightforward, and its efficiency is reliable.

Reciprocating compressors are available in various sizes for both commercial and residential air conditioning units.

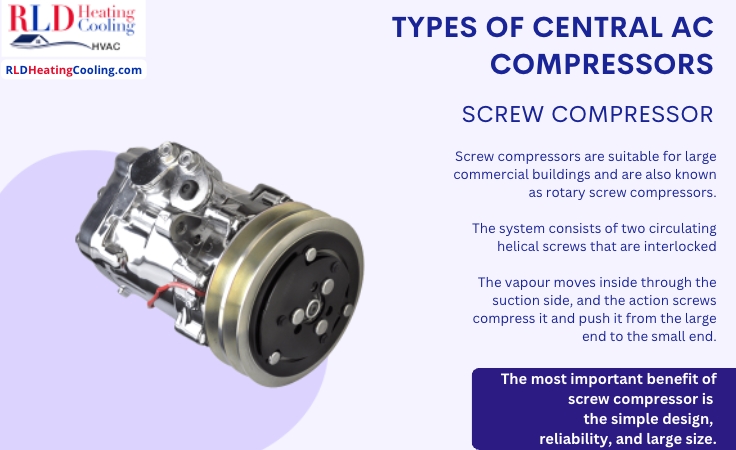

Central AC compressor type #4: Screw compressors

Screw compressors are suitable for large commercial buildings and are also known as rotary screw compressors.

The system consists of two interlocked circulating helical screws.

The vapor moves inside through the suction side, and the action screws compress it, pushing it from the large end to the small end.

The pressure inside becomes higher than the pressure in the discharge lines. It causes the valves to open, allowing the vapor to be discharged.

Some more refrigerant gas enters the suction, and the process continues.

Benefits

The most significant benefits are its simple design, reliability, and large size.

Most Rotary screw compressors are about 10 to 20 tons in size and are usually used in commercial applications.

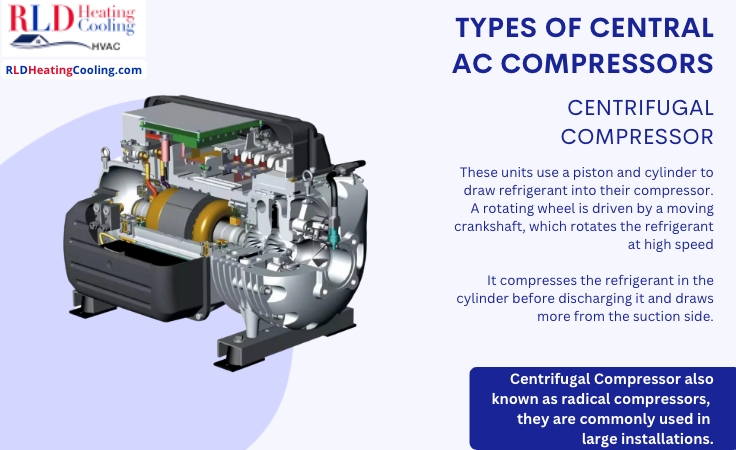

Central AC compressor type #5: Centrifugal compressors

These units use a piston and cylinder to draw refrigerant into their compressor.

A rotating wheel is driven by a moving crankshaft, which rotates the refrigerant at high speed.

It compresses the refrigerant in the cylinder before discharging it and draws more from the suction side.

Benefits

Also known as radical compressors, they are commonly used in large installations.

Centrifugal compressors are not suitable for residential use.

They are energy-efficient and more cost-effective to build than other commercial compressors.

Centrifugal compressors also produce higher continuous airflow than other commercial types, such as reciprocating compressors.

How to maintain your AC compressor?

All compressors must be maintained and well-maintained to ensure they operate at their best efficiency.

But how do we maintain the compressor?

Here are a few tips and hacks you should use to keep your AC compressor in good shape:

Central AC compressor maintenance tip #1: Check for any leakage in the seals

Check the seals on both suction and discharge lines. If there are any leakages, then you must replace the seals. Additionally, do not wait for a leak to replace your seals; instead, replace them preemptively during annual maintenance.

Central AC compressor maintenance tip #2: Clean the coils

Clean both the indoor and the outdoor coils regularly. If the coil is dirty, it might reduce heat transfer. It exerts considerable pressure on your compressor. The result is mechanical failure and reduced efficiency.

Central AC compressor maintenance tip #3: Changing the air filter in the air handler as required

Dirty filters, as we know, obstruct the free flow of air, causing your air conditioner to work harder than usual and reducing both its effectiveness and efficiency.

Cleaning and replacing air filters is also an integral part of your heating maintenance.

Central AC compressor maintenance tip #4: Clean the louvers

Also, don’t forget to clean the condenser unit jacket’s louvers. Leaves, debris, and dust particles obstruct airflow, causing the unit to work harder.

Central AC compressor maintenance tip #5: The refrigerant level

Check the refrigerant level annually. If the refrigerant level is low, it indicates a leak. An AC low on refrigerant will not condition your house effectively. Additionally, ensure that it is performed by an HVAC technician using the appropriate testing gauge.

Central AC compressor maintenance tip #6: Wrap your condenser unit in an insulated blanket

Don’t forget to wrap your condenser unit in a warm blanket during winter if your climate experiences extreme cold.

Central AC compressor maintenance tip #7: In summer, flip the high-pressure switch

Activate the high-pressure switch during the summer if your unit features a toggle switch for this purpose. Also, it might have a low-pressure switch that needs to be activated.

Central AC compressor maintenance tip #8: Protect the condenser unit from direct sun rays

Shield your condenser or outside unit from direct sunlight, as it may cause the compressor and coil to overheat, making it more difficult for them to discharge heat.

Central AC compressor maintenance tip #9: Keep the surroundings of your condenser clean

Trim the bushes, shrubs or overhanging tree branches that might restrict airflow into and from the condenser. These branches and plants, if left unchecked, might also grow inside the fan cabinet and damage the fan when it comes on.

Common problems with AC compressors

The good news is that the AC compressors are pretty durable.

The reason is that they are one of your AC unit’s essential and expensive segments.

The bad news, however, is that when compressors fail, it takes a toll on the entire AC unit, and replacing a compressor is an expensive affair.

So, here we list some of the problems that are common for your AC compressors:

Circulation issue

Often, our AC blows warm or normal air or the air isn’t cooling.

It usually happens because the refrigerant isn’t circulating the air in the indoor coil and capturing heat.

First, you must check if the system has been in heat or fan mode.

However, if it is in AC mode and you’re still not getting cool air, there might be a problem with the compressor, or there may also be refrigerant leakage, which typically requires emergency AC repair.

Working Too Hard / Overheating

Above, we mentioned that if the coils, fans, filters, and other components of your AC are not clean, it can restrict airflow, causing your AC to work overtime and blow warm air.

Tickling, clanking or hard starting

Is your compressor making excessive clanking or cracking noises while running?

It may be due to electrical issues, such as faulty or worn-out wires, or even AC capacitor failure.

Tripping circuits

If the electrical circuit of the compressor keeps tripping, it might be due to a bad compressor or an electrical issue.

It is a more cost-effective solution than replacing your compressor unit.

If the circuit or the breaker keeps tripping, ask a professional to check your system.

Overcharging refrigerant

Too much refrigerant is also not suitable for the AC.

High pressure can damage your compressor.

Therefore, if your AC starts to become problematic after a few days of installation, it is likely that the refrigerant levels are unacceptable.

Refrigerant contamination

Your AC system consists of a part known as a filter segment.

It is programmed to remove moisture from the refrigerant, allowing the gas to compress properly.

When moisture or other contaminants like dirt and debris enter your refrigerant, it can cause problems in your compressor.

So, if there is contamination in your refrigerant, take the help of a professional technician.

The compressor burned out

Another reason your AC may not be blowing cool air is that the compressor might be malfunctioning.

Adjust the thermostat and also keep an eye on the condenser unit outside.

If nothing happens or it starts making weird noises, the compressor has failed.

Again, get the unit checked by an HVAC technician and diagnose the problem quickly.

Refrigerant pressure problems

If the discharge pressure is too low or too high, it might result in your AC losing its cooling capacity.

If your unit is equipped with a pressure gauge, check the gas pressure against the actual or normal pressure specified in the manual.

Call an HVAC technician and have them inspect the AC compressor to troubleshoot if the pressure is off.

Compressor warranties

HVAC warranties, including those for compressors, have changed in the last few years, and different HVAC brands offer varying warranty models.

However, you should keep your condenser unit in good shape, irrespective of the warranty policy.

Different warranty policies are:

- Lifetime warranty.

- 12-year warranty.

- Ten-year warranty.

- Five-year warranty.

- Unit replacement warranty.

AC Compressor costs

Your AC compressor replacement costs around $1250-$$2,500 for most models.

The variable capacity compressor replacement costs a bit high at $ 3,300, including both installation and labor charges.

Let’s look at the price structure in detail:

- 12000-15000 BTUs- Average price 685$- Premium price 850$- Installation $1250-$1600.

- 18000-24000 BTUs- Average price $715- Premium price $945- Installation $1300 – $1850.

- 32000-36000 BTUs- Average price $780- Premium price $1050- Installation $1445- $2125.

- 42000-48000 BTUs- Average price $900- Premium price $1135- Installation $1650- $2280.

- 60000 BTUs- Average price $1150- Premium price $1485- Installation $1870- $2500.

The cost factors include:

- Size of the compressor – Since ACs range from about 18,000 to 60,000 BTUs for split systems, the price rises with the compressor’s size.

- Quality – Not all compressors are built equally. A higher price gives better quality.

- Stages – Single-stage compressors cost less than 2-stage compressors because of their operation. Variable capacity compressors are the costliest.

FAQs

Here are some of the questions people usually ask:

How do air conditioners work?

Air conditioners work by absorbing hot air from your house and throwing it outside using a chemical agent known as refrigerant(1).

Your AC unit has two parts:

- An indoor unit (Basically fitted into your room or closet)

- Outdoor unit (Placed on the roof or in the backyard.)

These two units are connected through a copper tubing known as a refrigerant, the same substance in your refrigerator that keeps your food items cool and fresh.

Liquid refrigerant flows through copper tubing to the indoor unit.

It absorbs and collects heat from your house, and the refrigerant converts the heat into a gas.

The gas then travels to the outdoor unit through the copper tubing.

At this point, the refrigerant releases the heat being carried outdoors via your AC’s condenser coils.

The agent then turns to a liquid form and travels into your indoor unit to absorb more heat, allowing your house to attain the desired cooling level.

What does a central AC compressor do?

Your central air conditioner’s compressor is the pump that pushes the refrigerant through your AC unit.

Without it, the refrigerant cannot travel through your air conditioner, making it impossible for your air conditioning system to cool your house.

In the central air conditioners, the compressor is fitted in the outdoor unit of your AC.

The compressor acts as the heart of your AC system, so if anything goes wrong with your compressor, it can directly impact your AC’s functioning.

Why is my compressor so difficult to repair?

AC compressors are challenging to repair because they have airtight sealing, and sometimes it even gets complicated for an HVAC technician to fix them.

The reason behind the difficulty is that the compressor parts are fitted in an airtight metal container that can only be opened by the AC manufacturer.

The advantage of this airtight sealing is that there is no leakage from the refrigeration system.

If the refrigerant leaks, it can cause severe respiratory issues.

The downside is that repairing a compressor is less cost-effective than replacing it because the equipment and time are too much.

How do I know if my compressor is broken?

There are several warning signs to look for if your compressor is malfunctioning. Here are some of them:

- If your AC blows warm air.

- Low airflow.

- Clicking and cranking noises around the outdoor unit of your AC.

- The circuit breaker is tripping frequently.

References

https://www.epa.gov/section608/stationary-refrigeration-leak-repair-requirements